Do-It-Yourself Dalek

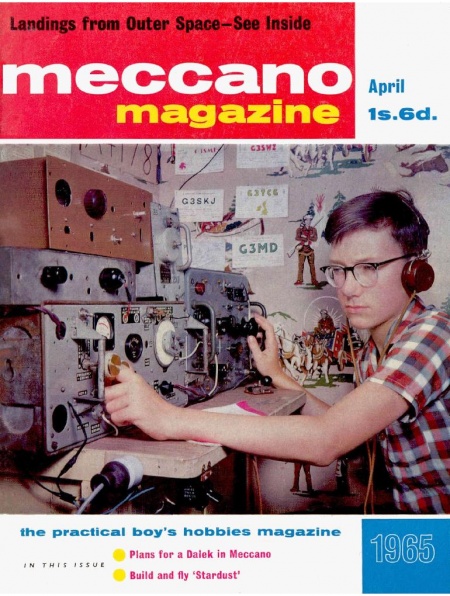

- Publication: Meccano Magazine

- Date: April 1965

- Author:

- Page: 31

- Language: English

WHILE travelling into the future in his incredible 'time machine', Dr. Who and his three companions encountered the fearsome Daleks These weird space invaders of the future are, as most of you know, to be seen on the exciting television serial 'Dr. Who'.

However, although the Daleks are in many ways frightening, they are fascinating creatures with strange metallic voices that have the ability to slip along, robot-like, under their own power. In fact, so popular are the Daleks that toy shops throughout the country have been selling thousands of models of these space creatures. Therefore, I thought it would make a popular exercise to build a Dalek in Meccano. The model described in this article is based on a television Dalek, although it is not identical in shape. Motive power is supplied by an Emebo motor and two lamps on the front of the body flash on and off as the model moves.

An Intriguing model based on B.B.C. Television's famous "Daleks".

A rectangle is built up from two 41 in. Angle Girders 1 and 2, and two 51 in. Angle Girders 3. Bolted to Angle Girder I are a 21 in. x 21 in. Insulating Flat Plate 4 (Elektrikit Part No. 511), a 41 in. Flat Girder 5 and four 71 in. Strips 6, the last arranged in two pairs, one each side of the Insulating Plate. At the top, the Strips making up each pair are overlapped, as shown and are bolted, along with a 31 in. Strip 7, to a Fishplate 8. Plate 4 is extended by a 5) in. x21 in. Insulating Flat Plate 9 (Elektrikit Part No. 510) which, in turn, is bolted to Strip 7, Twelve in. Washers are fixed in rows of three to Plates 4 and 9.

Two f in. x 1 in. Double Brackets 10, each carrying a Lamp Holder 11 (Elektrikit Part No. 539) and connected by a 2f in. Insulating Strip 12 (Elektrikit Part No. 502), are bolted to Plate 9. Half-inch Bolts are used to fix Insulating Strip 12 and the Lamp Holders to the Double Brackets. A Swivel Bearing 13, with a 31 in. Rod mounted in the spider, is attached to

The model viewed from beneath.

23

31

Strip 12 by means of a 1 in. Bolt through the centre hole. A

I in. Pulley 14 is fixed on the end of the 31 in. Rod. Lamps, of course, are fitted in the Lamp Holders.

Both sides are similarly built. A 71 in. Angle Girder 15 and two 71 in. Strips 16 and 17 are bolted, in the positions shown, to Angle Girder 3, at the same time fixing 51 in. Flat Girder 18 in place. The intervening space is filled in by a 74 in. Strip Plate 19, a 31 in. x 11 in. Triangular Flexible Plate 20, a .51 in. x 11 in. Flexible Plate 21 and a 34 in. x 2 in. Triangular Flexible Plate 22. A further two 71 in. Strips 23 and a 71 in. Strip Plate 24, all overlaid along the bottom by a 31 in. Flat Girder 25, are used to complete the back.

A square is formed from four 31 in. Angle Girders 26, and this is fixed to the top of the body, as shown, Fishplates connecting Strips 16 and 17 to the respective Girders.

The Head

Two circles 27 and 28 are each built up from two 54 in. Strips to which four Angle Brackets are bolted. Another three circles 29 are then built up from four 21 in. Stepped Curved Strips, the upper circle being braced by two 21 in. Strips 30. These Strips are connected by a further two 21 in. Strips 31 placed one on top of the other. All five circles are connected by eight 2 in. Screwed Rods, but are held apart by nuts on each Rod.

Fixed to the Boiler End 32 by a 1 in. Bolt is a Small Fork Piece that carries a Collar 33 between its arms. A 21 in. Rod, on which three f in. Washers, each spaced from the next by two Washers, are held by Collars, is mounted in this Collar. The Boiler End is placed on a 3 in. Pulley 34 and the two are fixed in place by another 2 in. Screwed Rod 35 held in Strips 31. Angle Brackets are used to secure the completed head to Girders 26.

Gearbox and Motor Drive

Two similar housing sides are constructed from a 51 in. Angle Girder 36 to which a 21 in. x 21 in. Flat Plate 37 is bolted. Journalled in the centre hole of the Flat Plates is a 31 in. Rod that carries a 60-tooth Gear Wheel 38, a in. Sprocket Wheel 39 and a Commutator 40 (Elektrikit Part No. 551). A Collar holds the Rod in place.

A view of the gearbox showing the drive and also the commutator arrangement.

The Wiring diagram.

Fixed between Plates 37 are two 21 in. x 1 in. Double Angle Strips 41 and 42, one of the bolts securing Double Angle Strip 41 also holding an Insulating Fishplate 43 (Elektrikit Part No. 513). Held on a in. Bolt, fixed in this Fishplate, is a 2 in. Wiper Arm 44 (Elektrikit Part No. 533), which is in contact with the outside edge of the Commutator. In contact with the continuous conduction part of the Commutator is a 11 in. Wiper Arm 45 (Elektrikit Part No. 532), mounted on a in. Bolt held in a 11 in. Insulating Strip 46 which is bolted to one of the Plates 37.

Another 31 in. Rod, carrying a Tia in. Pinion 47 and a 1 in. fixed Pulley 48 is journalled in Plates 37, then an Emebo Motor is bolted to Double Angle Strips 41 and 42. Pinion 47 is in constant mesh with Gear 38 and Pulley 48 is connected, by a 21 in. Driving Band, to a 1 in. Pulley on the Motor output shaft.

A 1 in. Corner Bracket 49 is bolted to each Angle Girder 36. Mounted in these is a third 31 in. Rod carrying a i in. Sprocket Wheel 50, and held in place by I in. Pulleys with Rubber Ring. Sprocket Wheels 39 and 50 are connected by Sprocket Chain. At the front, Girders 36 are bridged by a 21 in. Strip 51, to which a 1 in. x f in. Double Bracket is lock-nutted. Mounted in this Double Bracket is a If in. Rod, held in place by Collars, that carries a 1 in. loose Pulley 52, spaced from the lugs of the Bracket by Washers.

Finally, the completed arrangement is bolted to Angle Girders

1 and 2, as shown.

The Wiring

A length of wire is taken from one terminal of each Lamp Holder and is connected to Wiper Arm 44, then another wire is taken from the other terminal of each Lamp Holder to one terminal of a battery. The last wire connects Wiper Arm 45 to the remaining terminal of the battery. You will find a simple

diagram on this page, showing the wiring layout. Spanner

Parts required

10 of No. 1b 1 of No. 19b 12 of No. 90a 2 of No. 189

4 of No. 2 4 of No. 22 1 of No. 94 3 of No. 195

1 of No. 3 1 of No. 22a 2 of No. 96a 2 of No. 224

5 of No. 5 1 of No. 23a 2 of No. 103 2 of No. 225

2 of No. 8b 1 of No. 28c 2 of No. 103c 1 of No. 502

4 of No. 9 1 of No. 27d 2 of No. 111 1 of No. 503

2 of No. 9a 157 of No. 37a 4 or No. 111a 1 of No. 510

4 of No. 9b 95 of No. 37b 3 of No. 111c 1 of No. 511

8 of No. 10 37 of No. 38 1 of No. 116a 1 of No. 513

2 of No. 11 15 of No. 38d 2 of No. 133a I of No. 532

1 of No. lla 2 of No. 48a 2 of No. 155 1 of No. 533

10 of No. 12 7 of No. 59 1 of No. 162a 2 of No. 539

4 of No. 16 2 of No. 72 1 of No. 165 2 of No. 540

1 of No. 16a 9 of No. 81 1 of No. 186 1 of No. 551

1 of No. 18a 1 Emebo motor

49

- 30

/42

44

4,5

49

SAT TERY

32

Disclaimer: These citations are created on-the-fly using primitive parsing techniques. You should double-check all citations. Send feedback to whovian@cuttingsarchive.org

- APA 6th ed.: (April 1965). Do-It-Yourself Dalek. Meccano Magazine p. 31.

- MLA 7th ed.: "Do-It-Yourself Dalek." Meccano Magazine [add city] April 1965, 31. Print.

- Chicago 15th ed.: "Do-It-Yourself Dalek." Meccano Magazine, edition, sec., April 1965

- Turabian: "Do-It-Yourself Dalek." Meccano Magazine, April 1965, section, 31 edition.

- Wikipedia (this article): <ref>{{cite news| title=Do-It-Yourself Dalek | url=http://cuttingsarchive.org/index.php/Do-It-Yourself_Dalek | work=Meccano Magazine | pages=31 | date=April 1965 | via=Doctor Who Cuttings Archive | accessdate=15 December 2025 }}</ref>

- Wikipedia (this page): <ref>{{cite web | title=Do-It-Yourself Dalek | url=http://cuttingsarchive.org/index.php/Do-It-Yourself_Dalek | work=Doctor Who Cuttings Archive | accessdate=15 December 2025}}</ref>